CAM System

CAM system for programming

CNC machines with 2 – 5 axes:

Milling, turning, drilling.

CAM System With 2 – 5 Axes. Including Rough Milling.

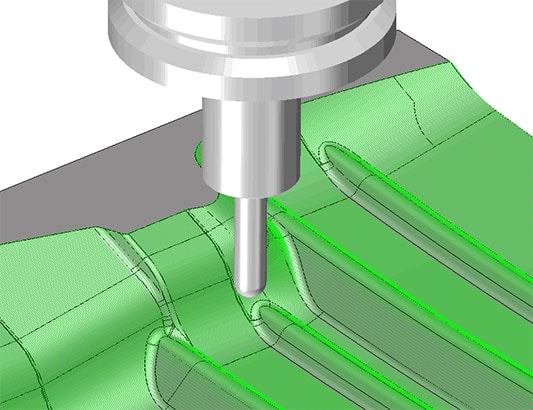

CAM Screenshots

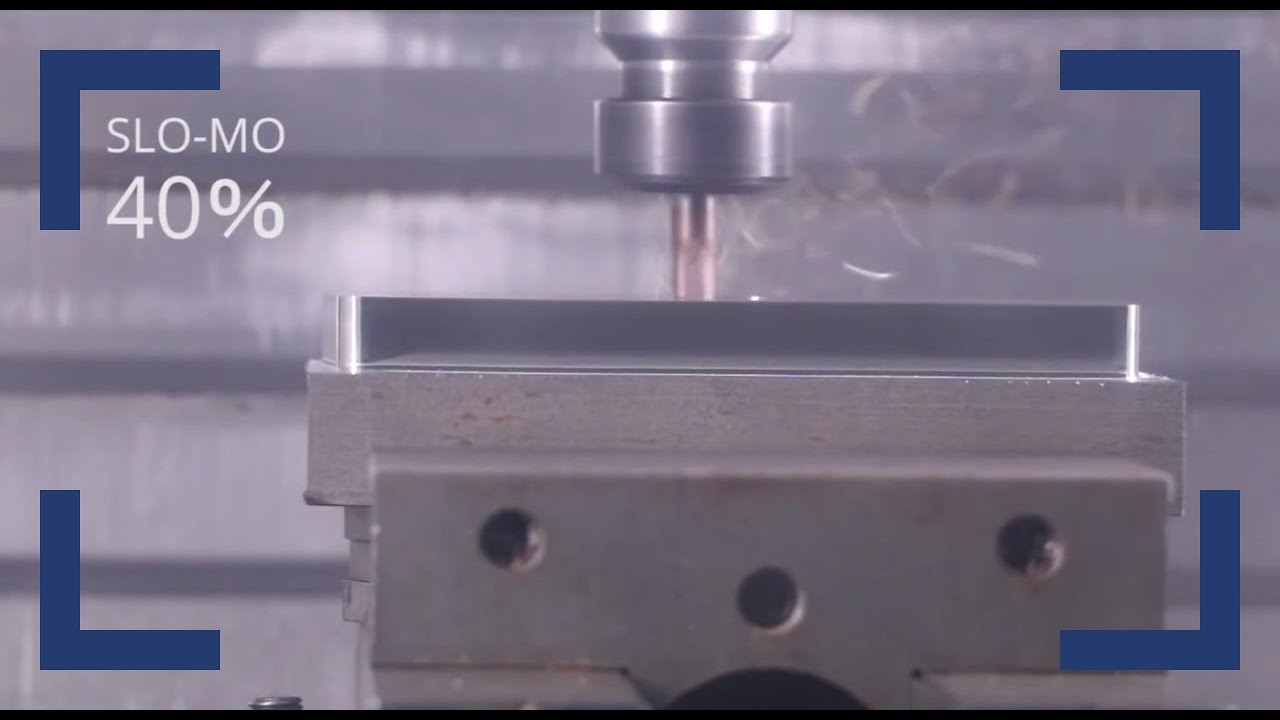

CNC programming with up to 5 axes – on request also simultaneously – including the possibility of highly efficient rough milling. A clear workflow with an intuitive Microsoft user interface allows you to get started quickly.

CAM software from ZWSOFT enables you to process productive milling over several axes for more than 40 machining variants.

This allows you to achieve efficient roughing, smooth finishing and productive high-speed milling.

The CAM programs enable turning with external and internal roughing, finishing, recessing, threading, transverse facing and drilling. The post processor offers you advanced post-processing functions. For example, for converting blade position data (APT-CL) into machine-specific code (GM code) that CNC machines require.

The CAM software solutions enable you to use productive CNC programming of your designs. Several post processors are available by default for handing over to the NC control of your machine. You can easily customize these post processors as needed.

Just like the CAD solutions from ZWSOFT, all CAD CAM software systems can be learned quickly and easily. With our ZWCAM training courses, you can get started from the very beginning and effectively right. This makes CNC programming fun and saves costs.

For a professionally structured management of your CAM data from the beginning, please take a look at our ZW3D PDM interface.

Please contact us if you need help with the installation or general support.

CAM Programs and Add-Ons

The all-rounder

ZW3D Premium

The all-in-one package for design and manufacturing.

The perfect CAD CAM system.

2-Axis Milling

ZW3D 2X Machinist

Basic 2-axis CAM functions for roughing and finishing operations.

Intelligent drilling for 2-5 axes manually or automatically.

Including the CAD functions of ZW3D Fundamental.

3 – 5-Axis Milling

ZW3D 3X Machinist

3-axis milling incl. Residual material machining (3-axis simultaneous + 2-axis tilt).

Intelligent drilling for 2-5 axes manually or automatically.

Including the CAD functions of ZW3D Fundamental.

Add-on 5-Axis Simultaneous

ZW3D 5X Simultaneous milling

The 5-axis simultaneous milling module enables simultaneous machining with up to 5 axes. STL data can also be edited directly.

Please contact us

Add-On Rough Milling

ZW3D VoluMill

VoluMill® is the preferred choice worldwide for high-speed rough milling.

VoluMill reduces programming and processing time, significantly increases tool productivity and tool life.

CAM Software Highlights and Functions (Selection)

In the following you will learn about some CAM features that you can use in ZW3D 2X-, 3X Machinist 2020 or VoluMill 2020.

Quickly Learned and Implemented

Whether professional or beginner: You can master all CAM product variants via a comparatively short learning curve. Workflows are clearly organized. The intuitive Microsoft user interface allows you to quickly find your way into the product.

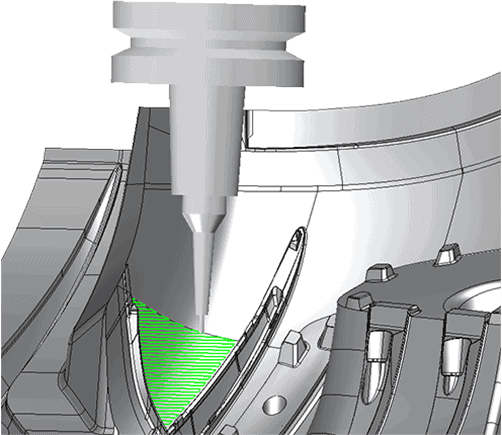

Intelligent and Reliable 2X Milling

The 2X milling and drilling automatic tactic defines features for you and automatically generates tool paths. This significantly reduces programming time. For 2X milling you have all the tools for easy control in your hand. Create easily and flexibly tool paths on 2D geometries and surfaces.

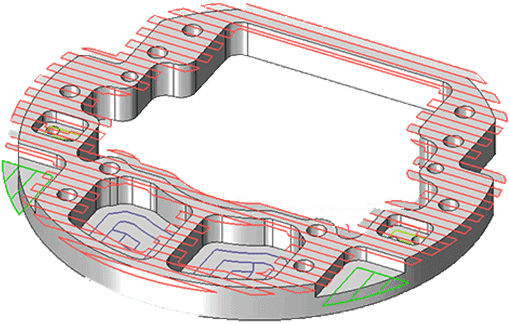

Smart Roughing Strategies with VoluMill

With the CAD CAM software VoluMill you create optimized tool paths and thus save around 50 – 80% ordinary processing times.

If the full milling depth is used in VoluMill, you will have much longer use of your cutting tool.

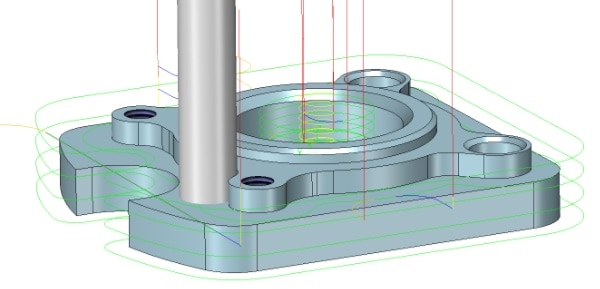

Productive 3X Milling

For efficient roughing, smooth finishing and productive high-speed milling, you can use over 40 machining methods in ZWCAM. For all work in production.

Desired tool paths can be realized not only via nurbs, but also via STL geometry. Undercut tool path inclusive.

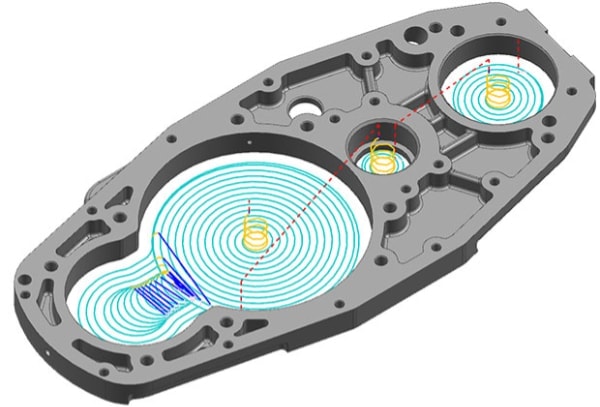

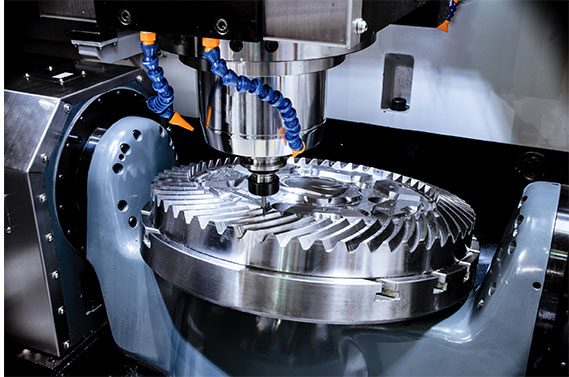

CAM Solution for 4- and 5-Axis Machining

You can machine up to 5 axes simultaneously using the 5-axis simultaneous milling module. You can also edit STL data directly. With the functions …

- Rollers

- Path curve

- Path area

- Contour parallel

- Z Constant

- Point control

- Conversion of the tool path from 3X to 5X

… expand the editing options for different scenarios.

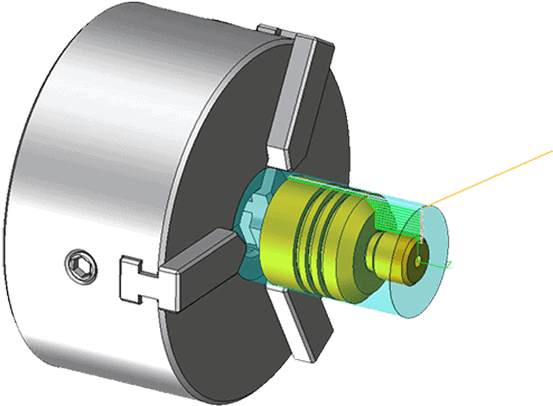

Intuitive Rotation

The turning function area offers you

- External and internal roughing

- Finishing

- Puncture

- Thread turning

- Cross-planning

- Drilling

for most types of turned parts.

Wiremodels, surfaces, and volumes are detected. Rotation cycles are supported.

Flexible Tool Path Editor

- The Tool Path Editor gives you better tool paths and better editing efficiency without tediously adjusting parameter settings and continuously recalculating the tool paths.

- Edit entire or partial tool paths with tools such as trimming, reordering, reconnecting, extending & transforming.

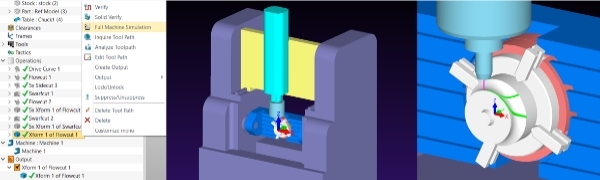

Reliable and Secure CAM Solution

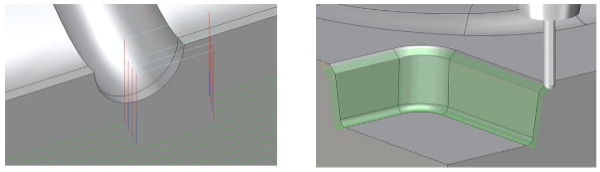

The CAM functions give you numerous options for a workable, reliable and safe processing:

With Solid Verify, you simulate the actual machining process and also analyze the excess materials. You benefit from efficient processing.

Using the analysis function, programmers detect collisions and surface injuries between tool and workpiece, terminals, table, etc.

The safety of your machining is guaranteed by the exact calculation of the minimum suspension length of the tool.

Post-Processing: The Post Processor

ZW3D Post enables advanced post-processing functions for converting blade position data (APT-CL) into machine-specific code (GM code). This is required by CNC machines.

- Support for all classes 3 – 5-axis milling machines

- Modern technology with Windows GUI

Machine Simulation: First Check

The AddOn Machine Simulation is an additional tool that helps you to develop optimal, efficient NC programs.

- Check the movements of your 3-axis, 4-axis, or 5-axis machines in advance.

- Detect any collisions between material, tools and other machine components at an early stage.

- Test possible multi-axis tensions and find the ideal clamping position for your machining jobs.

Your Next Step to CAM

- You want a CAD/CAM demo – free of charge?

- Or do you have any questions about the CAD CAM system?

Please fill out the form. We look forward to seeing you …

- You just want to test the program?

Here you go: Click here for the CAM download …