ZW3D Professional

ZW3D Professional offers sophisticated functions for tool, mold or model making. The ideal solution for your

design tasks.

ZW3D Professional: For 3D Tool

and Shape Construction

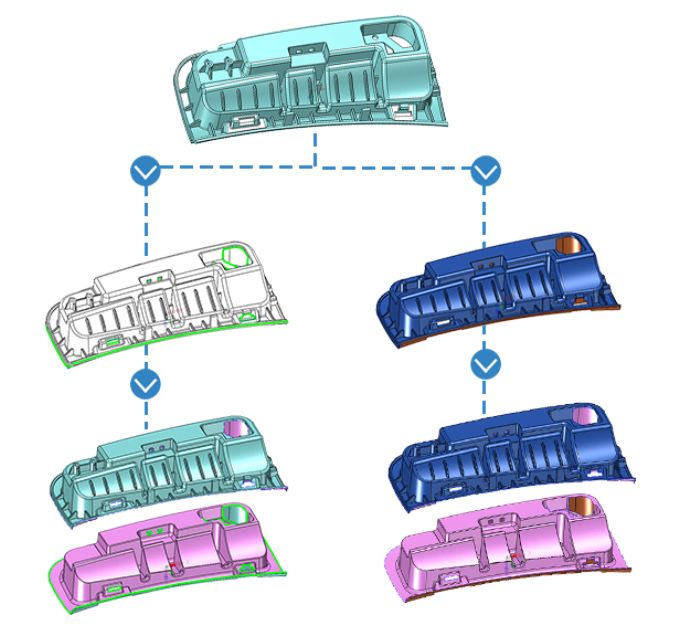

ZW3D Professional covers all requirements throughout the entire mould making process. High-quality data import, intelligent model healing, unique shape separation (even for defective external data), expandable shape-building and standard part libraries, practical electrode design incl. documentation is just a few features of this industry solution.

- Multi-cavity and multi-product design

- Separation lines and separators for shape and cavity – Automatic or interactive

- Automatic and interactive creation of nozzle + ejector side

- Curvature, undercut, wall thickness analysis

- Direct edit for solids and surfaces

- Tools for creating cooling and gating systems

- Slider generator

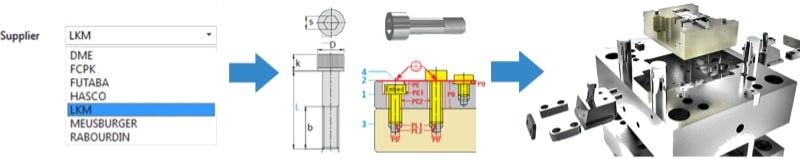

- Library for standard molded structures and standard parts

For Intuitive Working

ZW3D Professional automatically creates form cavities for you. The whole process can be done with little effort.

ZW3D Professional contains many commands for constructing articles. Also for the construction of cutting surfaces for tool and mould making. Or for the creation of devices.

With ZW3D you work intuitively through the complete design process. From the imported file to the assembly to the derivation of the drawing with sophisticated view functions.

With the electrode assistant, ZW3D Professional accelerates the creation of the mold electrode for sink roding. The offset of the electrode is processed automatically. The unique Planar option combines multiple electrodes, saving you up to 40% of your time compared to other methods.

Functions in detail:

- Fast electrode design

- Electrode blanks and automatic electrode creation

- Associative electrode tables and drawings

- With the reverse engineering functions (point cloud) you can quickly create complex 3D models from real existing parts. For example, you can 3D scan worn tools and components and edit and repair them with ZW3D

- Create and edit surfaces from 3D scan data

Typical Areas of Application

- Tooling

- Mold

- Modelling

- Electrode creation

Functions Mould and Tool Making in ZW3D Professional

Here are some mold and tool making features that you can use in ZW3D Professional 2020.

Here you can see all functions and in which product variant they are included.

Quickly Disconnect the Core and Cavity For Less Lead Times

- Save a lot of time by bypassing model healing and dividing parts directly through separators or surfaces.

- Use both automatic and manual creation of dividers, inner holes, and partitions. This greatly increases efficiency.

- With multi-cavity and multi-product design, you meet the different design requirements of different products.

Extensive Library with Mold Construction & Standard Parts of Different Standards

You can modify and personalize the integrated library with mold structure and standard parts at any time. All parts of the library meet the requirements of different countries and companies.

Special Tools for Detailed Mould Making

With special tools, you can quickly develop skids, cooling systems, sliders and various sprues. You can freely modify these depending on the practical requirements.

Flexible Solutions for Quick Handling of Complex Electrode Constructions

Quick creation of complex electrodes. Use the easy-to-use electrode extraction tools.

Automatically create a stack of electrodes as well as the 2D drawing. This dramatically reduces development time and reduces errors.